The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change, the transition to renewable energy has become more critical than ever. Renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. The importance of renewable energy lies not only in its potential to reduce greenhouse gas emissions but also in its ability to provide sustainable energy solutions for future generations. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, economic implications, global perspectives, future trends, and ultimately, the vision for a sustainable future powered by renewable energy. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their Impact 1. Brief History of Fossil Fuel UsageFossil fuels, including coal, oil, and natural gas, have been the backbone of industrial development since the 18th century. The Industrial Revolution marked a significant turning point, as societies transitioned from agrarian economies to industrialized ones, heavily reliant on fossil fuels for energy. This shift enabled unprecedented economic growth and technological advancements but also set the stage for environmental degradation. 2. Environmental ConsequencesThe extraction and combustion of fossil fuels have led to severe environmental consequences, including air and water pollution, habitat destruction, and climate change. The burning of fossil fuels releases carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming and its associated impacts, such as extreme weather events, rising sea levels, and biodiversity loss. B. The Emergence of Renewable Energy 1. Early Uses of Renewable EnergyThe use of renewable energy is not a new concept. Ancient civilizations harnessed wind and water for sailing and milling grain. The first recorded use of solar energy dates back to the 7th century B.C. when people used magnifying glasses to start fires. However, it wasn't until the late 19th and early 20th centuries that renewable energy began to gain traction as a viable alternative to fossil fuels. 2. Technological Advancements Leading to Modern Renewable EnergyThe 20th century saw significant technological advancements that paved the way for modern renewable energy systems. The invention of the photovoltaic cell in the 1950s marked a breakthrough in solar energy technology, while the development of wind turbines in the 1970s allowed for the harnessing of wind energy on a larger scale. These innovations, coupled with growing environmental awareness, set the stage for the renewable energy revolution we are witnessing today. III. Types of Renewable Energy A. Solar Energy 1. How Solar Panels WorkSolar energy is harnessed through photovoltaic (PV) cells, which convert sunlight directly into electricity. When sunlight hits the PV cells, it excites electrons, creating an electric current. This electricity can be used immediately, stored in batteries, or fed into the grid. 2. Benefits and Challenges of Solar EnergyThe benefits of solar energy are numerous: it is abundant, sustainable, and produces no emissions during operation. However, challenges remain, including the high initial costs of installation, the need for large areas for solar farms, and the intermittent nature of sunlight, which necessitates energy storage solutions. B. Wind Energy 1. Mechanism of Wind TurbinesWind energy is generated by converting the kinetic energy of wind into mechanical power using wind turbines. As wind passes over the blades of a turbine, it causes them to spin, which turns a generator to produce electricity. 2. Advantages and Limitations of Wind EnergyWind energy is one of the fastest-growing renewable energy sources, offering a clean and sustainable alternative to fossil fuels. It has a low environmental impact and can be deployed onshore and offshore. However, challenges include noise pollution, the impact on wildlife, and the variability of wind patterns. C. Hydropower 1. Overview of Hydroelectric Power GenerationHydropower is generated by harnessing the energy of flowing water, typically through dams. Water released from the reservoir flows through turbines, generating electricity. Hydropower accounts for a significant portion of the world's renewable energy supply. 2. Environmental Considerations and SustainabilityWhile hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption and changes to water quality. Sustainable practices, such as run-of-the-river systems and fish ladders, are essential to mitigate these effects. D. Biomass and Biofuels 1. Definition and Types of Biomass EnergyBiomass energy is derived from organic materials, such as plant and animal waste. It can be converted into biofuels, such as ethanol and biodiesel, or used directly for heating and electricity generation. 2. Role in Reducing Waste and Carbon EmissionsBiomass energy plays a dual role in waste management and energy production. By utilizing waste materials, biomass energy reduces landfill use and greenhouse gas emissions. However, it is essential to ensure that biomass is sourced sustainably to avoid deforestation and other negative environmental impacts. E. Geothermal Energy 1. Explanation of Geothermal SystemsGeothermal energy harnesses heat from the Earth's interior to generate electricity or provide direct heating. This is achieved by tapping into geothermal reservoirs, where hot water or steam is extracted and used to drive turbines. 2. Potential and Challenges of Geothermal EnergyGeothermal energy is a reliable and consistent energy source, with a small land footprint and low emissions. However, its potential is geographically limited to areas with suitable geological conditions, and the initial costs of drilling and infrastructure can be high. IV. The Role of Technology in Renewable Energy A. Innovations in Energy StorageEnergy storage technologies, such as batteries, are crucial for the widespread adoption of renewable energy. They allow for the storage of excess energy generated during peak production times for use during periods of low generation. Advancements in battery technology, including lithium-ion and solid-state batteries, are improving efficiency and reducing costs. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of energy distribution systems. By integrating digital communication and automation, smart grids can optimize energy flow, reduce outages, and facilitate the integration of renewable energy sources into the grid. C. The Role of Artificial Intelligence and Data Analytics in Optimizing Energy UseArtificial intelligence (AI) and data analytics are transforming the energy sector by enabling better demand forecasting, optimizing energy consumption, and improving the efficiency of renewable energy systems. AI can analyze vast amounts of data to identify patterns and make real-time adjustments, enhancing the overall performance of energy systems. V. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe transition to renewable energy is creating millions of jobs worldwide. From manufacturing solar panels to installing wind turbines, the renewable energy sector is a significant source of employment. According to the International Renewable Energy Agency (IRENA), the sector employed over 11 million people globally in 2018, with continued growth expected. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has plummeted in recent years, making it increasingly competitive with fossil fuels. According to the International Energy Agency (IEA), the cost of solar photovoltaic electricity has fallen by 82% since 2010, while onshore wind costs have decreased by 49%. As technology continues to advance, renewable energy is expected to become even more affordable. C. Government Policies and Incentives Promoting Renewable Energy AdoptionGovernment policies and incentives play a crucial role in promoting the adoption of renewable energy. Many countries offer tax credits, subsidies, and grants to encourage investment in renewable energy projects. Additionally, renewable energy targets and regulations are driving the transition away from fossil fuels. VI. Global Perspectives on Renewable Energy A. Case Studies of Countries Leading in Renewable EnergyCountries such as Germany, Denmark, and China are at the forefront of the renewable energy transition. Germany's Energiewende policy aims to transition to a sustainable energy system, with a target of generating 80% of its electricity from renewables by 2050. Denmark has become a leader in wind energy, generating over 40% of its electricity from wind turbines. China is the largest producer of solar panels and has invested heavily in renewable energy infrastructure. B. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, aim to unite countries in the fight against climate change. These agreements encourage nations to set ambitious targets for reducing greenhouse gas emissions and transitioning to renewable energy sources. Collaborative efforts, such as the International Renewable Energy Agency (IRENA), facilitate knowledge sharing and best practices among countries. C. Challenges Faced by Developing Countries in Adopting Renewable EnergyWhile many developed countries are making strides in renewable energy adoption, developing countries face unique challenges. Limited access to financing, inadequate infrastructure, and political instability can hinder the transition to renewable energy. However, innovative solutions, such as off-grid solar systems and community-based renewable energy projects, are emerging to address these challenges. VII. Future Trends in Renewable Energy A. Predictions for Renewable Energy GrowthThe future of renewable energy looks promising, with projections indicating significant growth in the coming decades. According to the IEA, renewable energy is expected to account for 80% of global electricity generation by 2050. This growth will be driven by advancements in technology, decreasing costs, and increasing demand for clean energy. B. Emerging Technologies and Their Potential ImpactEmerging technologies, such as floating solar farms, advanced energy storage systems, and hydrogen fuel cells, have the potential to revolutionize the renewable energy landscape. These innovations can enhance energy generation, storage, and distribution, making renewable energy more accessible and efficient. C. The Role of Public Awareness and Education in Promoting Renewable EnergyPublic awareness and education are crucial for driving the transition to renewable energy. As individuals become more informed about the benefits of renewable energy, they are more likely to support policies and initiatives that promote its adoption. Educational programs and community engagement efforts can empower individuals to take action and contribute to a sustainable future. VIII. ConclusionThe transition to renewable energy is not just a necessity; it is an opportunity to create a sustainable future for generations to come. By embracing renewable energy sources, we can reduce our reliance on fossil fuels, mitigate climate change, and foster economic growth. It is imperative that individuals, businesses, and governments work together to promote the adoption of renewable energy and invest in the technologies and infrastructure needed to support this transition. The vision for a sustainable future powered by renewable energy is within our reach, and it is up to us to make it a reality. IX. References1. International Renewable Energy Agency (IRENA). (2019). Renewable Energy and Jobs – Annual Review 2019.2. International Energy Agency (IEA). (2020). World Energy Outlook 2020.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.4. U.S. Department of Energy. (2021). Solar Energy Technologies Office.5. World Bank. (2020). The World Bank and Renewable Energy: A Global Perspective.This comprehensive exploration of renewable energy highlights its evolution, current state, and future potential. By understanding the importance of renewable energy and the role it plays in achieving sustainability, we can collectively work towards a cleaner, greener planet.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change, the need for sustainable energy solutions has never been more critical. Renewable energy, derived from natural processes that are replenished constantly, offers a viable path toward reducing greenhouse gas emissions and mitigating the impacts of global warming. This article explores the evolution of renewable energy, its various forms, technological advancements, economic implications, global perspectives, and future trends, ultimately underscoring the importance of transitioning to a sustainable energy future. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFor centuries, humanity has relied heavily on fossil fuels—coal, oil, and natural gas—as the primary sources of energy. The Industrial Revolution marked a significant turning point, as the demand for energy surged, leading to the widespread extraction and consumption of these resources. While fossil fuels powered economic growth and technological advancements, they also brought about severe environmental consequences, including air and water pollution, habitat destruction, and climate change. 1. Brief History of Fossil Fuel UsageThe use of fossil fuels dates back to ancient civilizations, but it was not until the 18th and 19th centuries that their extraction and use became industrialized. The invention of the steam engine and the internal combustion engine revolutionized transportation and manufacturing, further entrenching fossil fuels in the global economy. By the mid-20th century, fossil fuels accounted for over 80% of the world's energy consumption. 2. Environmental ConsequencesThe environmental impact of fossil fuel consumption is profound. The burning of coal, oil, and gas releases significant amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming. Additionally, oil spills, coal mining, and natural gas extraction have devastating effects on ecosystems and biodiversity. As awareness of these consequences grew, the search for cleaner, more sustainable energy sources intensified. B. The Emergence of Renewable EnergyIn response to the environmental challenges posed by fossil fuels, renewable energy began to gain traction in the late 20th century. Early uses of renewable energy can be traced back to ancient civilizations that harnessed wind and water for power. However, it was not until the 1970s energy crisis that significant investments were made in renewable technologies. 1. Early Uses of Renewable EnergyWindmills and waterwheels were among the first technologies to harness renewable energy. Wind energy was used for sailing ships and grinding grain, while hydropower was employed in mills and irrigation systems. The advent of solar energy can be traced back to the 19th century when the photovoltaic effect was discovered, leading to the development of solar cells. 2. Technological Advancements Leading to Modern Renewable EnergyThe late 20th century saw significant advancements in renewable energy technologies. The oil crises of the 1970s spurred research and development in solar, wind, and geothermal energy. By the 1990s, the commercialization of these technologies began to take off, driven by decreasing costs and increasing efficiency. Today, renewable energy is a rapidly growing sector, with innovations continuously reshaping the landscape. III. Types of Renewable EnergyRenewable energy encompasses a diverse range of sources, each with its unique characteristics, benefits, and challenges. The most prominent types of renewable energy include solar, wind, hydropower, biomass, biofuels, and geothermal energy. A. Solar Energy 1. How Solar Panels WorkSolar energy is harnessed through photovoltaic (PV) cells, which convert sunlight directly into electricity. When sunlight strikes the PV cells, it excites electrons, creating an electric current. Solar panels can be installed on rooftops, in solar farms, or integrated into building materials, making them versatile for various applications. 2. Benefits and Challenges of Solar EnergyThe benefits of solar energy are numerous. It is abundant, sustainable, and produces no emissions during operation. Additionally, solar energy can reduce electricity bills and increase energy independence. However, challenges remain, including the intermittent nature of sunlight, the need for energy storage solutions, and the environmental impact of manufacturing solar panels. B. Wind Energy 1. Mechanisms of Wind TurbinesWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. As wind passes over the blades of a turbine, it causes them to spin, which drives a generator to produce electricity. Wind farms can be located onshore or offshore, with offshore wind farms often benefiting from stronger and more consistent winds. 2. Advantages and Limitations of Wind EnergyWind energy is one of the fastest-growing renewable energy sources, offering significant advantages such as low operational costs and minimal environmental impact. However, challenges include the variability of wind, potential impacts on wildlife, and the need for suitable locations for wind farms. C. Hydropower 1. Overview of Hydroelectric Power GenerationHydropower harnesses the energy of flowing water to generate electricity. Dams are often constructed on rivers to create reservoirs, and as water flows through turbines, it generates electricity. Hydropower is one of the oldest and most established forms of renewable energy. 2. Environmental Considerations and SustainabilityWhile hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption and changes to water quality. Sustainable hydropower practices aim to minimize these impacts by considering ecological factors in the design and operation of hydroelectric facilities. D. Biomass and Biofuels 1. Definition and Types of Biomass EnergyBiomass energy is derived from organic materials, such as plant and animal waste. It can be converted into biofuels, such as ethanol and biodiesel, or used directly for heating and electricity generation. Biomass is considered renewable as long as it is sourced sustainably. 2. Role in Reducing Waste and Carbon EmissionsBiomass energy plays a dual role in waste management and energy production. By utilizing agricultural and forestry residues, biomass can reduce landfill waste while providing a renewable energy source. However, concerns about land use and emissions from biomass combustion must be addressed to ensure sustainability. E. Geothermal Energy 1. Explanation of Geothermal SystemsGeothermal energy harnesses heat from the Earth's interior to generate electricity or provide direct heating. Geothermal power plants tap into hot water or steam reservoirs underground, using the heat to drive turbines and produce electricity. 2. Potential and Challenges of Geothermal EnergyGeothermal energy is a reliable and consistent energy source, with a small land footprint and low emissions. However, its potential is geographically limited to areas with suitable geological conditions. Additionally, the initial costs of drilling and infrastructure can be high. IV. The Role of Technology in Renewable EnergyTechnological advancements have played a crucial role in the growth and efficiency of renewable energy sources. Innovations in energy storage, smart grid technology, and artificial intelligence are transforming the energy landscape. A. Innovations in Energy StorageEnergy storage technologies, such as batteries, are essential for addressing the intermittent nature of renewable energy sources like solar and wind. Advances in battery technology, including lithium-ion and solid-state batteries, are improving energy storage capacity, efficiency, and lifespan, enabling a more reliable energy supply. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of electricity distribution. By integrating digital communication and automation, smart grids can optimize energy flow, reduce outages, and facilitate the integration of renewable energy sources. This technology empowers consumers to manage their energy use and supports the transition to a decentralized energy system. C. The Role of Artificial Intelligence and Data Analytics in Optimizing Energy UseArtificial intelligence (AI) and data analytics are revolutionizing energy management. AI algorithms can analyze vast amounts of data to predict energy demand, optimize energy production, and enhance grid stability. By leveraging these technologies, energy providers can improve efficiency and reduce costs while maximizing the use of renewable energy sources. V. Economic Implications of Renewable EnergyThe transition to renewable energy has significant economic implications, including job creation, cost competitiveness, and government policies that promote adoption. A. Job Creation in the Renewable Energy SectorThe renewable energy sector is a major driver of job creation. According to the International Renewable Energy Agency (IRENA), the global renewable energy workforce reached 12 million jobs in 2020, with continued growth expected. Jobs in solar, wind, and energy efficiency are particularly prominent, offering opportunities for skilled labor and economic development. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has declined dramatically in recent years, making it increasingly competitive with fossil fuels. According to the International Energy Agency (IEA), the levelized cost of electricity (LCOE) for solar and wind has fallen by over 80% since 2010. As technology continues to advance and economies of scale are realized, renewable energy is poised to become the dominant energy source. C. Government Policies and Incentives Promoting Renewable Energy AdoptionGovernment policies play a crucial role in promoting renewable energy adoption. Incentives such as tax credits, grants, and feed-in tariffs encourage investment in renewable technologies. Additionally, regulations aimed at reducing carbon emissions and promoting clean energy can drive the transition to a more sustainable energy system. VI. Global Perspectives on Renewable EnergyThe transition to renewable energy is a global phenomenon, with countries around the world adopting various strategies to increase their renewable energy capacity. A. Case Studies of Countries Leading in Renewable Energy Adoption 1. Germany's EnergiewendeGermany's Energiewende, or "energy transition," is a comprehensive policy framework aimed at transitioning to a sustainable energy system. The country has made significant investments in renewable energy, particularly wind and solar, and aims to phase out nuclear power and reduce greenhouse gas emissions by 80-95% by 2050. 2. China’s Investment in Solar and Wind EnergyChina is the world's largest producer and consumer of renewable energy. The country has invested heavily in solar and wind energy, leading the world in installed capacity. China's commitment to renewable energy is driven by the need to address air pollution and reduce reliance on fossil fuels. B. Challenges Faced by Developing Countries in Transitioning to Renewable EnergyWhile many developed countries are making strides in renewable energy adoption, developing countries face unique challenges. Limited access to financing, inadequate infrastructure, and political instability can hinder the transition to renewable energy. However, international cooperation and investment can help overcome these barriers. C. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, play a vital role in promoting global cooperation on climate change and renewable energy. These agreements set targets for reducing greenhouse gas emissions and encourage countries to invest in clean energy technologies. VII. Future Trends in Renewable EnergyThe future of renewable energy is bright, with numerous trends and innovations shaping the landscape. A. Predictions for Renewable Energy GrowthAccording to the IEA, renewable energy is expected to account for nearly 90% of the increase in global power generation by 2025. As technology continues to advance and costs decline, the share of renewables in the global energy mix will only increase. B. Emerging TechnologiesInnovations such as floating solar farms, advanced wind turbines, and energy-efficient building materials are on the rise. Floating solar farms, for example, utilize bodies of water to install solar panels, reducing land use and increasing energy generation. Advanced wind turbines are designed to capture more energy at lower wind speeds, enhancing efficiency. C. The Role of Public Awareness and EducationPublic awareness and education are crucial for promoting renewable energy adoption. As individuals and communities become more informed about the benefits of renewable energy, they are more likely to support policies and initiatives that promote sustainability. Educational programs and outreach efforts can empower citizens to make informed energy choices. VIII. ConclusionThe transition to renewable energy is essential for combating climate change and achieving a sustainable future. As we have explored, renewable energy sources offer numerous benefits, including reduced emissions, job creation, and energy independence. However, challenges remain, and it is imperative that individuals, businesses, and governments work together to overcome these obstacles.The vision for a sustainable future powered by renewable energy is within reach. By embracing innovation, investing in clean technologies, and fostering public awareness, we can create a world where renewable energy is the norm, not the exception. The time to act is now—our planet's future depends on it. IX. References1. International Renewable Energy Agency (IRENA). (2020). Renewable Energy and Jobs – Annual Review 2020.2. International Energy Agency (IEA). (2021). World Energy Outlook 2021.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.4. German Federal Ministry for Economic Affairs and Energy. (2020). The Energy Transition.5. China National Energy Administration. (2020). Renewable Energy Development in China.This comprehensive exploration of renewable energy highlights its evolution, current state, and future potential, emphasizing the critical role it plays in achieving a sustainable and resilient energy future.

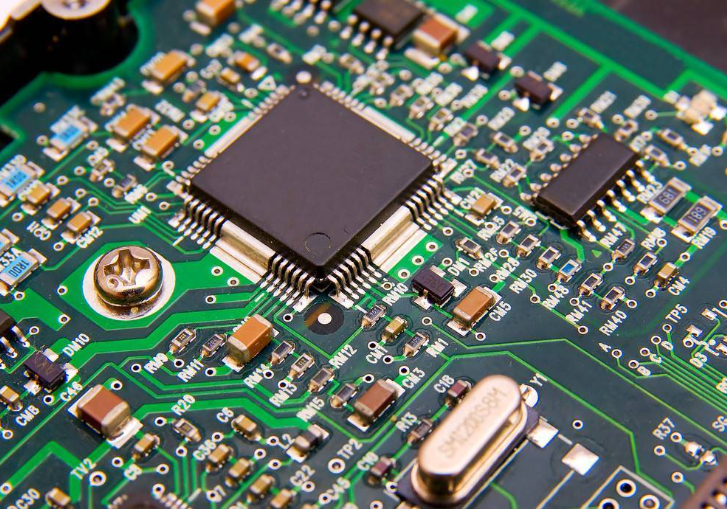

Popular Models of Common Chokes IntroductionIn modern electronic devices, chokes play a crucial role as important inductive components. They can suppress high-frequency noise, filter, and stabilize current in circuits. With the continuous development of electronic technology, the application range of chokes is expanding, covering multiple fields such as power management and signal processing. This article aims to introduce some popular models of chokes and their applications, helping readers better understand the function of chokes and choose the appropriate models. 1. Basic Concepts of Chokes 1.1 Working Principle of ChokesA choke is an inductive component that utilizes the characteristics of inductance to store energy and suppress changes in current. When current passes through a choke, the inductance generates a magnetic field, storing energy. When the current changes, the choke produces a reverse electromotive force, thereby suppressing rapid changes in current. This characteristic allows chokes to effectively suppress high-frequency noise in circuits and protect other components from normal operation. 1.2 Classification of ChokesChokes can be classified according to different standards:Classification by material:Ferrite choke: with good magnetic properties, suitable for high-frequency applications.Air choke: without a magnetic core, suitable for low-frequency applications.Aluminum choke: with high conductivity, suitable for high-current applications.Classification by application:Power chokes: used in power circuits, mainly for filtering and stabilizing current.Signal chokes: used in signal processing circuits, mainly for suppressing high-frequency noise. 2. Introduction to Common Choke Models 2.1 Power Chokes **Model 1: Wurth Elektronik 744373**Specifications: - Inductance: 10μH - DC Resistance: 0.015Ω - Saturation Current: 20A - Package Size: 7.0mm x 7.0mm x 5.0mmApplications: Wurth Elektronik 744373 is widely used in DC-DC converters, LED driver power supplies, and other power management applications to effectively reduce power noise and improve power stability. **Model 2: Coilcraft 1008**Specifications: - Inductance: 4.7μH - DC Resistance: 0.020Ω - Saturation Current: 15A - Package Size: 10.0mm x 8.0mm x 4.0mmApplications: Coilcraft 1008 is suitable for various power circuits, especially in applications requiring high current and low resistance, such as power modules and battery management systems. 2.2 Signal Chokes **Model 3: Murata LQH3N**Specifications: - Inductance: 1μH - DC Resistance: 0.015Ω - Saturation Current: 3A - Package Size: 3.2mm x 3.2mm x 2.0mmApplications: Murata LQH3N is mainly used in audio and video signal processing circuits to effectively suppress high-frequency noise and ensure signal clarity and stability. **Model 4: Bourns SRR0805-220M**Specifications: - Inductance: 22μH - DC Resistance: 0.1Ω - Saturation Current: 1.5A - Package Size: 8.0mm x 5.0mm x 4.0mmApplications: Bourns SRR0805-220M is suitable for various signal processing applications, especially in cases requiring high inductance value and low DC resistance, such as RF circuits and communication equipment. 2.3 High-Frequency Chokes **Model 5: Panasonic ERJ-3GEYJ**Specifications: - Inductance: 0.1μH - DC Resistance: 0.005Ω - Saturation Current: 5A - Package Size: 3.2mm x 1.6mm x 1.0mmApplications: Panasonic ERJ-3GEYJ is widely used in high-frequency circuits, such as RF amplifiers and wireless communication devices, to effectively suppress high-frequency interference. **Model 6: TDK MLP2012**Specifications: - Inductance: 1.5μH - DC Resistance: 0.020Ω - Saturation Current: 3A - Package Size: 2.0mm x 1.2mm x 1.0mmApplications: TDK MLP2012 is suitable for various high-frequency applications, especially in cases requiring miniaturization and high performance, such as mobile devices and portable electronic products. 3. Selection Guide for Chokes 3.1 Key Parameters for Choosing ChokesWhen selecting chokes, it is necessary to consider the following key parameters:Inductance: Choose the appropriate inductance value according to the circuit requirements. Generally, the larger the inductance value, the stronger the ability to suppress high-frequency noise.DC Resistance: The lower the DC resistance, the less energy loss and the higher the efficiency.Saturation Current: Choose a choke with a saturation current greater than the maximum current in the circuit to avoid saturation affecting performance.Package Size: Choose the appropriate package size according to the space limitations of the circuit board. 3.2 Analysis of Application ScenariosDifferent application scenarios have different requirements for chokes. In power management applications, it is usually necessary to choose power chokes, focusing on inductance value and saturation current; while in signal processing applications, signal chokes need to be selected, focusing on high-frequency characteristics and DC resistance. Therefore, when choosing chokes, it is necessary to consider the specific application requirements comprehensively. 4. Installation and Usage Precautions for Chokes 4.1 Installation TipsWhen installing chokes, pay attention to the following points:Correct soldering: Ensure that the solder joints are firm to avoid virtual soldering or short circuits.Avoid common installation errors: Such as polarity errors, position errors, etc., which may cause the choke to not work properly. 4.2 Maintenance during UseDuring use, it is essential to regularly check the performance of the chokes. Pay attention to the following points:Regular inspection and replacement: Regularly check the appearance and performance of the chokes, and replace them promptly if any abnormalities are found.Determine if performance has degraded: By measuring the inductance value and DC resistance, determine if the performance of the chokes has degraded to ensure the normal operation of the circuit. 5. Future Trends for Chokes 5.1 Application of New MaterialsWith technological advancements, the application of new materials will positively impact the performance of chokes. For example, using high-permeability materials can increase the inductance value, reduce DC resistance, and improve the overall performance of chokes. 5.2 Changes in Market DemandWith the continuous development of electronic products, the market demand for chokes is constantly changing. In the future, with the popularization of emerging technologies such as 5G and the Internet of Things, the demand for chokes in high-frequency applications and miniaturization will continue to grow, presenting significant market potential. ConclusionChokes play a crucial role in modern electronic devices, and their selection and application directly impact the performance and stability of circuits. Understanding popular models of chokes and their applications can help engineers make more informed choices when designing circuits. Looking ahead, with the application of new materials and changes in market demand, the development of chokes will bring new opportunities and challenges. References- "Electronic Components Handbook"- "Inductor Design and Application"- Official websites of major electronic component manufacturersThrough the above content, we have gained a deeper understanding of popular models of common chokes and their applications, hoping to provide readers with assistance in practical applications.

Guide to Choosing Stock Coils IntroductionIn modern industrial and electronic equipment, stock coils are an important electrical component widely used in motors, transformers, electronic components, and other fields. The choice of stock coils directly affects the performance and reliability of the equipment, so choosing the right coil is crucial. This article aims to provide readers with a practical guide to choosing stock coils, helping everyone make wise decisions among many options. 1. Understanding the Basics of Stock Coils 1. Types of Stock CoilsStock coils can be divided into various types based on material, specifications, and applications.Different materials: Common coil materials include copper and aluminum. Copper coils are widely used for their excellent conductivity and heat resistance, while aluminum coils have a place in some applications due to their lightweight and lower cost.Different specifications: The diameter and thickness of the coil are important parameters to consider when choosing. Different specifications will affect the inductance value and current-carrying capacity of the coil.Different applications: Coils are used in various applications, including motors, transformers, electronic components, etc. Coils for different applications also differ in design and material selection. 2. Key Characteristics of Stock CoilsWhen choosing stock coils, understanding their key characteristics is crucial.Conductivity: Conductivity is one of the core characteristics of a coil, directly affecting the efficiency of current transmission. Copper coils have better conductivity than aluminum coils, but aluminum coils can also meet requirements in some cases.Heat resistance: Coils generate heat during operation, so heat resistance is a factor to consider when choosing. In high-temperature environments, choosing coils with good heat resistance can effectively extend their service life.Mechanical strength: Coils may be subjected to mechanical stress during use, so their mechanical strength is also an important consideration. Coils with high strength can better resist external impacts and vibrations. 2. Key Factors in Choosing Stock Coils 1. Application RequirementsThe first step in choosing stock coils is to clearly define their specific use. Different application scenarios have different requirements for coils.Specific use of coils: For example, coils used in motors need to have high heat resistance and conductivity, while coils used in transformers need to consider the relationship between inductance value and number of turns.Working environment: The working environment of the coil will also affect its selection. In high-temperature, high-humidity, or chemically corrosive environments, it is particularly important to choose coils that are corrosion-resistant and heat-resistant. 2. Material SelectionMaterial selection directly affects the performance and cost of the coil.Pros and cons of copper coils vs. aluminum coils: Copper coils have better conductivity but are more expensive; aluminum coils are relatively cheaper but have slightly lower conductivity. Choosing the right material based on specific requirements is key.Applicability of other materials: In some special applications, coils made of other materials (such as nickel, iron, etc.) may be required, and these materials may exhibit better performance under specific conditions. 3. Coil SpecificationsThe choice of coil specifications is equally important.Selection of diameter and thickness: The diameter and thickness of the coil will affect its inductance value and current-carrying capacity. Generally, a larger diameter results in a higher inductance value, but it also increases costs.Relationship between number of turns and inductance value: The more turns a coil has, the higher the inductance value usually is, but it also increases the size and weight of the coil. Therefore, a comprehensive consideration is needed when choosing. 4. Quality StandardsQuality standards are an important factor to consider when choosing stock coils.Relevant certifications: Choosing products with certifications such as ISO, CE, etc., can ensure their quality and safety.Production processes and quality control: Understanding the supplier's production processes and quality control procedures can help assess the reliability of their products. 3. Choosing a SupplierChoosing the right supplier is a crucial step in ensuring the quality of coils. 1. Supplier Reputation and ExperienceIndustry reputation: Choosing a supplier with a good reputation in the industry can reduce risks.Past customer cases: Reviewing a supplier's past customer cases can help assess the suitability and reliability of their products. 2. Supplier's Product RangeCustomization services: In some cases, custom coils may be needed, so choosing a supplier that can provide customization services can better meet requirements.Stock availability: Understanding a supplier's stock availability can ensure timely delivery and avoid production delays due to stockouts. 3. After-Sales ServiceReturn and exchange policy: Choosing a supplier with a good return and exchange policy can help resolve issues promptly.Technical support and consulting services: The technical support and consulting services provided by the supplier can help customers better understand product characteristics and applications. 4. Price and Cost Analysis 1. Price FactorsMaterial costs: The prices of coils made from different materials vary significantly, so a comprehensive consideration of material costs and performance is necessary.Impact of production processes on prices: Complex production processes may lead to price increases, so a balance is needed when choosing. 2. Cost-Benefit AnalysisLong-term benefits of choosing high-quality coils: Although high-quality coils have higher initial costs, their reliability and efficiency in long-term use can bring higher returns.Potential risks of low-cost coils: Low-cost coils may save costs in the short term, but their potential failure risks and higher maintenance costs may lead to overall losses. 5. Case Studies 1. Success CaseA company, when choosing stock coils, conducted detailed requirements analysis and market research, and ultimately selected a high-quality copper coil. The coil performed excellently in high-temperature environments, greatly improving equipment efficiency, reducing failure rates, and the company thereby gained substantial economic benefits. 2. Failure CaseAnother company, in choosing coils, pursued low prices and ultimately selected a low-quality aluminum coil. The coil frequently malfunctioned during use, causing production line downtime, resulting in significant economic losses and reputational damage. 6. Summary and RecommendationsWhen choosing stock coils, it is necessary to consider multiple factors such as application requirements, material selection, coil specifications, quality standards, and supplier reputation. It is recommended that readers maintain caution and rationality during the selection process, conduct in-depth research on their own needs, to ensure the selection of the most suitable coil. References- Industry standards and regulations- Relevant books and research papers- Official websites of suppliers and manufacturers ConclusionChoosing the right stock coils is not only about the performance and reliability of the equipment but also about the economic benefits of the company. It is hoped that this article can provide valuable references for readers in the selection process, helping everyone make wise decisions.

Mainstream Capacitor Product Series Parameters IntroductionCapacitors are an essential part of electronic components, mainly used for storing electrical energy and releasing it when needed. Capacitors play various roles in circuits such as smoothing currents, filtering, coupling, and decoupling, and are widely used in consumer electronics, communication devices, industrial control, and other fields. With the continuous advancement of technology, the types and performance of capacitors are constantly improving. This article aims to introduce the mainstream capacitor product series and their parameters to help readers better understand the characteristics and applications of capacitors. 2. Basic Classification of CapacitorsCapacitors can be classified according to different standards, mainly including material, structure, and application aspects. 1. Classification by MaterialCeramic Capacitors: Using ceramic material as the dielectric, they have high stability and reliability, suitable for high-frequency circuits.Aluminum Electrolytic Capacitors: Using aluminum foil as the electrode and electrolyte as the dielectric, they have a large capacitance and are commonly used in power circuits.Tantalum Capacitors: Using tantalum metal as the electrode, they have high capacitance and stability, suitable for high-frequency and high-temperature environments.Film Capacitors: Using film material as the dielectric, they have low loss and high stability, suitable for audio and industrial control. 2. Classification by StructureSurface Mount Capacitors (SMD): Suitable for modern electronic devices with small design, convenient for automated production.Through-Hole Capacitors: Traditional capacitor type, suitable for high power and high voltage applications. 3. Classification by ApplicationGeneral Capacitors: Suitable for various common circuits.High-Frequency Capacitors: Designed for high-frequency signals, with low loss.Filter Capacitors: Used for smoothing power supply output and reducing electrical noise. 3. Mainstream Capacitor Product Series and Parameters 1. Ceramic CapacitorsCeramic capacitors are one of the most common types of capacitors, widely used in consumer electronics and communication devices.Product Series:X7R: Wide capacitance range and good temperature characteristics, suitable for general applications.C0G: Excellent temperature stability and low distortion, suitable for high-precision circuits.Y5V: Wide capacitance range but poor temperature characteristics, suitable for applications with low accuracy requirements.Main Parameters:Capacitance Range: 1pF to 100μFVoltage Rating: From 16V to 1000VTemperature Coefficient: X7R (-55°C to +125°C), C0G (-55°C to +125°C), Y5V (-30°C to +85°C)Size: 0402, 0603, 0805, and other various packagesApplications: Consumer electronics, communication devices, automotive electronics, etc. 2. Aluminum Electrolytic CapacitorsAluminum electrolytic capacitors are widely used in power supplies and audio devices due to their high capacitance and relatively low cost.Product Series:High-Temperature Type: Suitable for high-temperature environments, with a longer service life.Low Impedance Type: With low equivalent series resistance (ESR), suitable for high-frequency applications.Main Parameters:Capacitance Range: 1μF to 10000μFVoltage Rating: From 6.3V to 450VESR: Typically between 10mΩ and 100ΩLife Span: Usually from 1000 hours to 10000 hours, depending on operating temperature and voltageApplications: Power supplies, audio devices, industrial equipment, etc. 3. Tantalum CapacitorsTantalum capacitors are favored for their high capacitance and small size, widely used in portable devices and medical equipment.Product Series:Solid Tantalum Capacitors: With high stability and reliability, suitable for high-frequency and high-temperature environments.Wet Tantalum Capacitors: Suitable for applications with high capacitance requirements.Main Parameters:Capacitance Range: 0.1μF to 1000μFVoltage Rating: From 4V to 100VESR: Typically between 10mΩ and 100ΩSize: Relatively small, suitable for limited space applicationsApplications: Portable devices, medical equipment, automotive electronics, etc. 4. Film CapacitorsFilm capacitors are widely used for their low loss and high stability, especially in the audio and industrial control fields.Product Series:Polypropylene Capacitors: With low loss and high stability, suitable for high-frequency applications.Polyester Capacitors: Suitable for general applications, relatively low cost.Main Parameters:Capacitance Range: 1nF to 100μFVoltage Rating: From 50V to 1000VTemperature Coefficient: Typically between -40°C and +85°CDistortion: Low, suitable for audio applicationsApplications: Audio devices, industrial control, medical equipment, etc. 4. Factors Affecting Capacitor ParametersThe performance of capacitors is influenced by various factors, mainly including temperature, voltage, and frequency. 1. Impact of Temperature on Capacitor PerformanceTemperature changes affect the capacitance and voltage rating of capacitors. Generally, an increase in temperature leads to a decrease in capacitance, especially for ceramic capacitors and aluminum electrolytic capacitors. Therefore, when selecting capacitors, the temperature range of their working environment needs to be considered. 2. Effect of Voltage on Capacitor LifespanThe lifespan of capacitors is closely related to their operating voltage. Operating beyond the rated voltage can accelerate the aging of capacitors and even lead to failure. Therefore, when designing circuits, ensure that the operating voltage of capacitors is below 80% to 90% of their rated value. 3. Influence of Frequency on Capacitor CharacteristicsFrequency variations affect the equivalent series resistance (ESR) and capacitance of capacitors. In high-frequency applications, the ESR of capacitors significantly affects their performance, so it is necessary to choose the appropriate type of capacitor for high-frequency applications. 5. Capacitor Selection GuideWhen selecting capacitors, consider multiple factors to ensure they are suitable for specific application requirements. 1. Choose the Appropriate Capacitor Type Based on Application RequirementsDifferent types of capacitors are suitable for different application scenarios. For example, ceramic capacitors are suitable for high-frequency applications, while aluminum electrolytic capacitors are suitable for power circuits. 2. Consider the Operating Environment of the CapacitorThe operating environment of the capacitor has a significant impact on its performance. Factors such as temperature, humidity, and voltage need to be considered to select the appropriate capacitor. 3. Evaluate the Cost-Effectiveness of CapacitorsWhen selecting capacitors, consider not only their performance but also evaluate their cost-effectiveness. Choosing capacitors with high cost-effectiveness can reduce overall design costs. 6. Future Trends in CapacitorsWith the continuous advancement of technology, capacitor technology is also constantly developing, mainly reflected in the following aspects. 1. Application of New MaterialsThe application of new materials will drive the improvement of capacitor performance. For example, using nanomaterials and new polymers can increase the capacitance and stability of capacitors. 2. Miniaturization and High PerformanceAs electronic devices move towards miniaturization and high performance, capacitors need to continuously reduce in size while improving their performance to meet market demands. 3. Environmental Protection and Sustainable DevelopmentEnvironmental protection and sustainable development have become global hot topics, and capacitor manufacturers are actively exploring environmentally friendly materials and production processes to reduce environmental impact. 7. ConclusionCapacitors play an important role in modern electronic devices, and their diversity and wide application make them indispensable components in electronic design. Understanding the mainstream capacitor product series and their parameters can help engineers make wiser choices when designing circuits. Choosing the right capacitors can not only improve circuit performance but also extend the lifespan of the equipment. 8. References1. "Capacitor Technology and Applications" - Electronic Components and Technology Conference2. "Understanding Capacitor Specifications" - IEEE Transactions on Components, Packaging and Manufacturing Technology3. "Capacitor Selection Guide" - Digi-Key Electronics4. "The Role of Capacitors in Electronic Circuits" - Electronics Tutorials5. "Advancements in Capacitor Technology" - Journal of Electronic MaterialsThe above is a detailed introduction to the mainstream capacitor product series and their parameters, hoping to provide readers with valuable information and guidance.

Latest Purchasing Models of Resistor Devices Components Introduction 1.1 Importance of Resistors in Electronic DevicesResistors are one of the most basic components in electronic circuits, with the main function of limiting current flow, dividing voltage, and adjusting the working state of the circuit. Whether in simple household appliances or complex industrial equipment and high-tech products, resistors play a crucial role. With the continuous development of electronic technology, the performance and application range of resistors are also expanding. 1.2 Challenges and Opportunities in Purchasing ResistorsWhen purchasing resistors, engineers and procurement personnel face various challenges, including a wide range of models in the market, rapid technological updates, and price fluctuations. However, this also provides opportunities for companies to enhance product performance and competitiveness by selecting the right resistors. 1.3 Purpose and Structure of This ArticleThis article aims to explore the latest purchasing models of resistors, analyze market trends, recommend specific models, and provide considerations for purchasing. By gaining a deep understanding of resistors, readers can make wiser decisions during the procurement process. 2. Basic Concepts of Resistors 2.1 Definition and Function of ResistorsA resistor is an electronic component that can limit the flow of current, with its main function being to provide a specific resistance value to control the current and voltage in the circuit. The working principle of resistors is based on Ohm's Law, where current is directly proportional to voltage and inversely proportional to resistance. 2.2 Classification of ResistorsResistors can be classified according to different standards, including the following categories: 2.2.1 Fixed ResistorsFixed resistors are resistors whose resistance value is determined during manufacturing and does not change during use. Common fixed resistors include carbon film resistors, metal film resistors, and wirewound resistors. 2.2.2 Variable ResistorsVariable resistors allow users to adjust the resistance value as needed, with common types including potentiometers and rheostats. They are widely used in volume control, brightness adjustment, and other applications. 2.2.3 Special ResistorsSpecial resistors include thermistors, photoresistors, etc., whose resistance values change with temperature or light intensity, widely used in temperature sensors and light sensors. 3. Market Trends of the Latest Resistors 3.1 Impact of Technological Advancements on ResistorsWith the continuous advancement of electronic technology, the design and manufacturing processes of resistors are also constantly improving. For example, using advanced materials and manufacturing techniques can improve the accuracy and stability of resistors to meet the requirements of high-performance electronic devices. 3.2 Application of New MaterialsThe application of new materials has significantly improved the performance of resistors. For example, using nanomaterials and conductive polymers can produce smaller, lighter, and more efficient resistors to meet the requirements of modern electronic products for miniaturization and high performance. 3.3 Requirements for Environmental Protection and Sustainable DevelopmentWith the increasing environmental awareness, many companies have begun to use environmentally friendly materials and processes in the production of resistors to reduce environmental impact. At the same time, market demands for sustainable development are driving resistor manufacturers to innovate and develop more environmentally friendly products. 4. Purchasing Models of the Latest Resistors 4.1 Common Brands and ModelsIn the resistor market, many well-known brands offer high-quality resistor products. Here are some common brands and their models: 4.1.1 VishayVishay is a global leading manufacturer of electronic components, known for its high precision and reliability in resistor products. 4.1.2 YageoYageo is a Taiwanese electronic component manufacturer, offering a variety of resistor types widely used in consumer electronics and industrial equipment. 4.1.3 PanasonicPanasonic, as a well-known electronics manufacturer, has been widely recognized for the performance and quality of its resistor products. 4.1.4 BournsBourns focuses on providing high-performance resistors and other electronic components, widely used in communication, automotive, and industrial control fields. 4.2 Specific Model RecommendationsHere are some specific model recommendations for the latest resistors: 4.2.1 Vishay CR060310K00KThis resistor has high precision and low temperature drift characteristics, suitable for high-demand electronic devices. 4.2.2 Yageo RC060310K0FThis Yageo resistor has good stability and reliability, suitable for use in consumer electronic products. 4.2.3 Panasonic ERJ-3GEYJ103VThis Panasonic resistor is favored for its compact design and high power rating, suitable for applications with limited space. 4.2.4 Bourns 3296W-1-103LFThis variable resistor is suitable for applications that require adjusting resistance values, such as audio devices and sensors. 4.3 Characteristics and Application Scenarios of Each ModelEach model of resistor has its unique characteristics and application scenarios. For example, Vishay CR060310K00K is suitable for high-precision measurements, while Yageo RC060310K0F is more suitable for mass-produced consumer electronic products. Understanding these characteristics can help procurement personnel choose the most suitable resistors. 5. Considerations for Purchasing Resistors 5.1 Selection of Specifications and ParametersWhen purchasing resistors, it is essential to consider the following key parameters: 5.1.1 Resistance RangeChoosing the appropriate resistance range is crucial based on the requirements of the circuit design. Different application scenarios have different requirements for resistance values, and procurement personnel need to choose accordingly. 5.1.2 Power RatingThe power rating of a resistor determines the maximum power it can withstand, and when choosing, ensure that the power rating is higher than the actual power generated in the circuit. 5.1.3 Temperature CoefficientThe temperature coefficient refers to the degree to which the resistance value changes with temperature. Choosing resistors with a low temperature coefficient can improve the stability of the circuit. 5.2 Supply Chain Management 5.2.1 Supplier SelectionChoosing reliable suppliers is crucial to ensure the quality and delivery time of resistors. Procurement personnel should comprehensively evaluate the supplier's reputation, product quality, and service. 5.2.2 Delivery Time and Inventory ManagementReasonable delivery time and inventory management can effectively reduce procurement costs and ensure the smooth operation of production lines. 5.3 Cost Control and BudgetingCost control is an important factor to consider when purchasing resistors. Procurement personnel should choose resistor models based on the budget to ensure cost-effective procurement while meeting performance requirements. 6. Future Development Directions of Resistors 6.1 Trends in Smart and DigitalizationWith the development of smart and digitalization technologies, the application of resistors is also evolving. In the future, resistors will be combined with smart sensors, IoT devices, etc., to provide more efficient solutions. 6.2 Emerging Application Areas (such as IoT, 5G, etc.)The rapid development of IoT and 5G technologies provides new opportunities for the application of resistors. Resistors will play an important role in smart homes, smart transportation, industrial automation, and other fields. 6.3 Continuous Innovation and R&D InvestmentTo meet market demands, resistor manufacturers need to continuously innovate and invest in R&D to develop higher-performance, more environmentally friendly resistor products. 7. Conclusion 7.1 Summary of Key Points for Purchasing the Latest ResistorsWhen purchasing the latest resistors, it is important to consider the basic concepts of resistors, market trends, specific models and their characteristics, purchasing considerations, and other aspects. By gaining a comprehensive understanding of relevant information about resistors, companies can make more informed decisions during the procurement process. 7.2 Outlook for the Future Resistor MarketIn the future, the resistor market will continue to evolve with technological advancements and developments in emerging application areas. Companies should keep up with market trends, seize opportunities, and enhance their competitiveness. 8. References 8.1

Market Prospects Analysis of Unclassified Keywords IntroductionIn today's digital age, analyzing market prospects is crucial for strategic planning of businesses. Keywords, as the core elements of digital marketing, directly impact brand exposure and user conversion rates. However, with the continuous changes in the market, unclassified primary keywords have gradually attracted the attention of industry experts. Unclassified keywords refer to search terms that have not been clearly categorized, these keywords usually have high diversity and breadth, covering a wider range of user needs. This article aims to analyze the market potential of unclassified keywords from multiple perspectives and explore their importance in future digital marketing. 1. Market Background 1.1 Evolution of Digital MarketingThe rapid development of digital marketing has made businesses increasingly rely on the use of keywords to promote products and services. Compared to traditional marketing, digital marketing can more accurately reach target audiences, and keywords are the key tools to achieve this goal. Traditional marketing often relies on extensive advertising and brand awareness, while digital marketing can more effectively identify the needs of target audiences through data analysis and user behavior research.In digital marketing, the selection and use of keywords are crucial. Keywords not only affect the effectiveness of search engine optimization (SEO), but also directly relate to the precision of advertising placement. With the continuous updates of search engine algorithms, keyword classification and management have become increasingly complex. Businesses need to continuously adjust and optimize keyword strategies to adapt to market changes. 1.2 Current Status of Keyword ClassificationCurrently, commonly used methods for keyword classification in the market include long-tail keywords, short-tail keywords, brand keywords, etc. Long-tail keywords usually have lower search volume, but due to their specificity, they can bring higher conversion rates; short-tail keywords have large search volume, but high competition and relatively lower conversion rates. Brand keywords are search terms related to specific brands, usually with high brand loyalty.However, many businesses often overlook the potential value of unclassified keywords when formulating marketing strategies. The diversity and breadth of unclassified keywords make them an untapped market opportunity. With the changing consumer search behavior, the market potential of unclassified keywords is gradually emerging. 2. Definition and Characteristics of Unclassified Keywords 2.1 What are Unclassified KeywordsUnclassified keywords refer to search terms that have not been clearly categorized. These keywords are usually not included in the existing keyword classification system, possibly due to their uniqueness, ambiguity, or novelty. Examples of unclassified keywords include some emerging product names, popular trend vocabulary, or specific user needs. 2.2 Characteristics of Unclassified KeywordsThe characteristics of unclassified keywords include their diversity and potential high search volume. Because these keywords have not been fully utilized, businesses can gain a competitive advantage by exploring these keywords. Unclassified keywords often cover a wider range of user needs, satisfying consumers' desire for information diversity.Additionally, the search volume of unclassified keywords may increase over time, especially when certain trends or events occur. This dynamic nature makes unclassified keywords highly flexible and adaptable in marketing. 3. Market Potential of Unclassified Keywords 3.1 Changing User NeedsWith the evolution of consumer search behavior, users' demand for information diversity and personalization is increasing. Traditional keyword classification methods may not meet the complex needs of consumers, while unclassified keywords can provide more choices and possibilities. When searching, consumers often want to find the most relevant information to their needs, and unclassified keywords can fill this gap.For example, with the rise of social media, users' search behavior has become more diversified. They are not only looking for products or services, but also seeking information related to their interests, hobbies, and lifestyles. Unclassified keywords can help businesses better understand and meet these needs. 3.2 Competitive AnalysisMany competitors may overlook the potential of unclassified keywords, providing forward-thinking businesses with the opportunity to use these keywords. Through effective market analysis, businesses can stand out in competition. The exploration and application of unclassified keywords can help businesses find new growth points in the competitive market.For example, some startups have successfully attracted a large number of new users and increased sales by focusing on unclassified keywords. These businesses are often able to establish a unique brand image in the market, attracting consumers who are not interested in traditional brands. 3.3 Industry Application CasesBusinesses in different industries have begun to explore the application of unclassified keywords. For example, some e-commerce platforms have successfully attracted a large number of new users and increased sales by analyzing unclassified keywords. Through in-depth analysis of user search behavior, these platforms can identify potential market opportunities and adjust products and marketing strategies in a timely manner.In the travel industry, some travel agencies have discovered new travel trends and destinations through the exploration of unclassified keywords, leading to the launch of targeted travel products. This flexible market response capability allows these businesses to gain an advantage in competition. 4. Challenges of Unclassified Keywords 4.1 Difficulty of Data Analysis and MiningAlthough unclassified keywords have potential value, effectively identifying and analyzing these keywords remains a challenge. Businesses need to invest resources in data processing and analysis to extract valuable information. The diversity and complexity of unclassified keywords make the process of data analysis more difficult.Businesses can use advanced data analysis tools and techniques to help identify unclassified keywords. For example, using Natural Language Processing (NLP) technology can better understand user search intent, thereby identifying potential unclassified keywords. 4.2 Development of Marketing StrategiesDeveloping marketing strategies for unclassified keywords requires integration with existing strategies, posing higher demands on the marketing team of businesses. How to effectively integrate these keywords will be a major challenge for businesses. Businesses need to fully consider the characteristics and potential value of unclassified keywords when formulating marketing strategies.Additionally, businesses need to continuously monitor and evaluate the performance of unclassified keywords to make timely adjustments to strategies. The dynamic nature of unclassified keywords requires businesses to have the ability to adapt flexibly. 5. Future Development Trends 5.1 Impact of Technological Advancements on Unclassified KeywordsWith the continuous advancement of artificial intelligence and machine learning technologies, businesses will become more efficient in identifying and analyzing unclassified keywords. The application of these technologies will provide new momentum for the market development of unclassified keywords. Through automated data analysis and mining, businesses can quickly identify potential unclassified keywords and formulate corresponding marketing strategies.For example, using machine learning algorithms, businesses can analyze user search behavior, identify trends and changes in unclassified keywords. The application of this technology will greatly enhance the competitiveness of businesses in the market. 5.2 Changing Market DemandIn the future, the demand for personalized content by consumers will further drive the application of unclassified keywords. Businesses need to adjust their strategies in a timely manner to adapt to this change. Unclassified keywords can help businesses better meet consumers' personalized needs, thereby enhancing user experience and brand loyalty.With the continuous changes in the market, the application of unclassified keywords will become increasingly important. Businesses need to continuously explore and tap into the potential of unclassified keywords to maintain a competitive advantage in the market. 6. ConclusionIn conclusion, unclassified keywords have broad prospects in the market. Businesses should actively explore the potential of unclassified keywords, formulate corresponding marketing strategies, and seize this market opportunity. Additionally, future research should focus on the further development and application of unclassified keywords. Through effective market analysis and data mining, businesses can find new growth points in competition and achieve sustainable development. References- Relevant research literature and market reports to support the views and analysis in the article. Market Prospects Analysis of Unclassified Keywords IntroductionIn today's digital age, analyzing market prospects is crucial for strategic planning of businesses. Keywords, as the core elements of digital marketing, directly impact brand exposure and user conversion rates. However, with the continuous changes in the market, unclassified primary keywords have gradually attracted the attention of industry experts. Unclassified keywords refer to search terms that have not been clearly categorized, these keywords usually have high diversity and breadth, covering a wider range of user needs. This article aims to analyze the market potential of unclassified keywords from multiple perspectives and explore their importance in future digital marketing. 1. Market Background 1.1 Evolution of Digital MarketingThe rapid development of digital marketing has made businesses increasingly rely on the use of keywords to promote products and services. Compared to traditional marketing, digital marketing can more accurately reach target audiences, and keywords are the key tools to achieve this goal. Traditional marketing often relies on extensive advertising and brand awareness, while digital marketing can more effectively identify the needs of target audiences through data analysis and user behavior research.In digital marketing, the selection and use of keywords are crucial. Keywords not only affect the effectiveness of search engine optimization (SEO), but also directly relate to the precision of advertising placement. With the continuous updates of search engine algorithms, keyword classification and management have become increasingly complex. Businesses need to continuously adjust and optimize keyword strategies to adapt to market changes. 1.2 Current Status of Keyword ClassificationCurrently, commonly used methods for keyword classification in the market include long-tail keywords, short-tail keywords, brand keywords, etc. Long-tail keywords usually have lower search volume, but due to their specificity, they can bring higher conversion rates; short-tail keywords have large search volume, but high competition and relatively lower conversion rates. Brand keywords are search terms related to specific brands, usually with high brand loyalty.However, many businesses often overlook the potential value of unclassified keywords when formulating marketing strategies. The diversity and breadth of unclassified keywords make them an untapped market opportunity. With the changing consumer search behavior, the market potential of unclassified keywords is gradually emerging. 2. Definition and Characteristics of Unclassified Keywords 2.1 What are Unclassified KeywordsUnclassified keywords refer to search terms that have not been clearly categorized. These keywords are usually not included in the existing keyword classification system, possibly due to their uniqueness, ambiguity, or novelty. Examples of unclassified keywords include some emerging product names, popular trend vocabulary, or specific user needs. 2.2 Characteristics of Unclassified KeywordsThe characteristics of unclassified keywords include their diversity and potential high search volume. Because these keywords have not been fully utilized, businesses can gain a competitive advantage by exploring these keywords. Unclassified keywords often cover a wider range of user needs, satisfying consumers' desire for information diversity.Additionally, the search volume of unclassified keywords may increase over time, especially when certain trends or events occur. This dynamic nature makes unclassified keywords highly flexible and adaptable in marketing. 3. Market Potential of Unclassified Keywords 3.1 Changing User NeedsWith the evolution of consumer search behavior, users' demand for information diversity and personalization is increasing. Traditional keyword classification methods may not meet the complex needs of consumers, while unclassified keywords can provide more choices and possibilities. When searching, consumers often want to find the most relevant information to their needs, and unclassified keywords can fill this gap.For example, with the rise of social media, users' search behavior has become more diversified. They are not only looking for products or services, but also seeking information related to their interests, hobbies, and lifestyles. Unclassified keywords can help businesses better understand and meet these needs. 3.2 Competitive AnalysisMany competitors may overlook the potential of unclassified keywords, providing forward-thinking businesses with the opportunity to use these keywords. Through effective market analysis, businesses can stand out in competition. The exploration and application of unclassified keywords can help businesses find new growth points in the competitive market.For example, some startups have successfully attracted a large number of new users and increased sales by focusing on unclassified keywords. These businesses are often able to establish a unique brand image in the market, attracting consumers who are not interested in traditional brands. 3.3 Industry Application CasesBusinesses in different industries have begun to explore the application of unclassified keywords. For example, some e-commerce platforms have successfully attracted a large number of new users and increased sales by analyzing unclassified keywords. Through in-depth analysis of user search behavior, these platforms can identify potential market opportunities and adjust products and marketing strategies in a timely manner.In the travel industry, some travel agencies have discovered new travel trends and destinations through the exploration of unclassified keywords, leading to the launch of targeted travel products. This flexible market response capability allows these businesses to gain an advantage in competition. 4. Challenges of Unclassified Keywords 4.1 Difficulty of Data Analysis and MiningAlthough unclassified keywords have potential value, effectively identifying and analyzing these keywords remains a challenge. Businesses need to invest resources in data processing and analysis to extract valuable information. The diversity and complexity of unclassified keywords make the process of data analysis more difficult.Businesses can use advanced data analysis tools and techniques to help identify unclassified keywords. For example, using Natural Language Processing (NLP) technology can better understand user search intent, thereby identifying potential unclassified keywords. 4.2 Development of Marketing StrategiesDeveloping marketing strategies for unclassified keywords requires integration with existing strategies, posing higher demands on the marketing team of businesses. How to effectively integrate these keywords will be a major challenge for businesses. Businesses need to fully consider the characteristics and potential value of unclassified keywords when formulating marketing strategies.Additionally, businesses need to continuously monitor and evaluate the performance of unclassified keywords to make timely adjustments to strategies. The dynamic nature of unclassified keywords requires businesses to have the ability to adapt flexibly. 5. Future Development Trends 5.1 Impact of Technological Advancements on Unclassified KeywordsWith the continuous advancement of artificial intelligence and machine learning technologies, businesses will become more efficient in identifying and analyzing unclassified keywords. The application of these technologies will provide new momentum for the market development of unclassified keywords. Through automated data analysis and mining, businesses can quickly identify potential unclassified keywords and formulate corresponding marketing strategies.For example, using machine learning algorithms, businesses can analyze user search behavior, identify trends and changes in unclassified keywords. The application of this technology will greatly enhance the competitiveness of businesses in the market. 5.2 Changing Market DemandIn the future, the demand for personalized content by consumers will further drive the application of unclassified keywords. Businesses need to adjust their strategies in a timely manner to adapt to this change. Unclassified keywords can help businesses better meet consumers' personalized needs, thereby enhancing user experience and brand loyalty.With the continuous changes in the market, the application of unclassified keywords will become increasingly important. Businesses need to continuously explore and tap into the potential of unclassified keywords to maintain a competitive advantage in the market. 6. ConclusionIn conclusion, unclassified keywords have broad prospects in the market. Businesses should actively explore the potential of unclassified keywords, formulate corresponding marketing strategies, and seize this market opportunity. Additionally, future research should focus on the further development and application of unclassified keywords. Through effective market analysis and data mining, businesses can find new growth points in competition and achieve sustainable development. References- Relevant research literature and market reports to support the views and analysis in the article.